I live in a safe area with negligible theft. Nonetheless, I recently decided to install a minimal security safe/lock-box – one that will keep certain items from the eyes and fingers of basically honest people that visit my home, such as visiting tradesmen, cleaners or house guests. No safe is theft proof and my need is for a container that would require defacing or damaging it in order to access the interior. Such a safe would not deter a dishonest person but would prevent tempting basically honest visitors. My caveat – I know that the safe that I am about to discuss is useless against a true thief .

The Chinese made small (23 x 17 x 17 cm) electronic safe that I purchased via eBay cost me $18.95 including shipping from California. See Fig 1 & 2, below.

Fig. 1 – EBay Listing

Fig. 2 – Electronic Safe

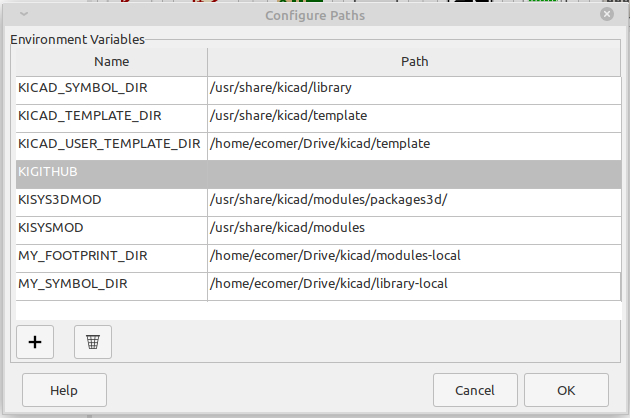

I was aware of the faults outlined by several YouTube reviews, such as YouTube user mepickulongtime but felt that I could improve its utility and at this price it would be an interesting exercise even if I failed. Most, if not all similar electronic safes that make a mechanical “click” when the correct combination is entered, use a solenoid to temporarily unlock[1] the door. Safes, such as on cruise ships and many hotels, that emit a motor running sound when the correct combination is entered to open or close, do not use a solenoid and are thus secure from a “bump-open, although they do have other vulnerabilities that I won’t discuss here. There are many nearly identical solenoid locked electronic safes. Some are identical and others have mostly cosmetic differences. While several Chinese manufacturers may be copying each other’s products, it is more likely that small “factories” buy common components and assemblies from the same suppliers and the final safes’s differences are minor and superficial. For example, sellers on alibaba.com sell the entire insides of this type of safe for $3 in quantity 100. See Fig 3, below. Small Chinese shops can build or buy a steel box, insert the safe “guts”, add some cosmetics and bingo – they are a safe manufacturer. BTW – sellers on alibaba sell this entire safe, exactly as I purchased, for as little as $5, in quantity 1,000.

Fig. 3 – wholesale safe “guts”

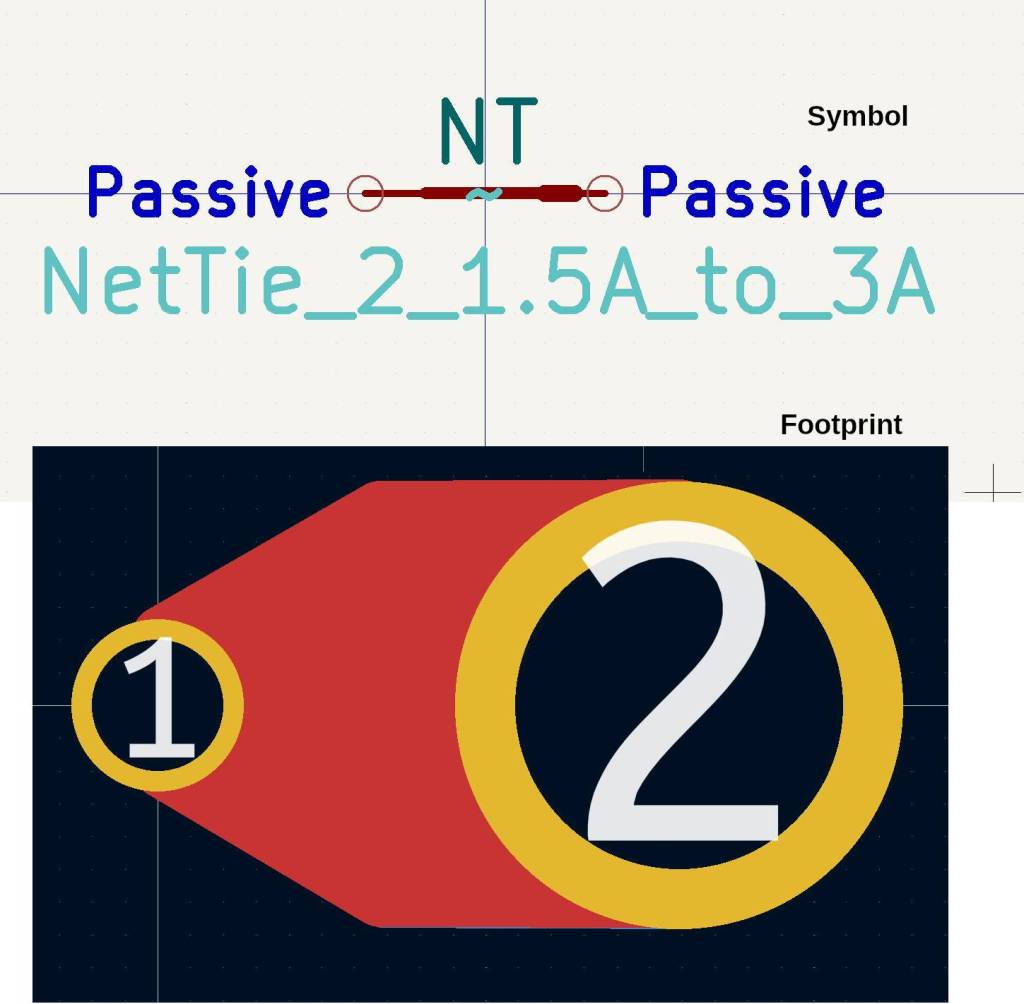

The solenoid used in this safe is shown in Fig. 4, below, where I “exploded” it for a better view.

Fig 4. – Exploded View of Solenoid

Ebay’s safes are generic but the branded ones sold by Harbor-Freight, Amazon, Honeywell and others have virtually identical solenoid mechanisms.

I intended to add a couple of the improvements outlined by YouTube user HifiCentret and YouTube user “Ben J”. I felt that HifiCentret’s improvements would elevate this safe’s usefulness. However, once I discovered significant deficiency I stopped. The metallic looking plastic opening lever actuator (T-Bar) on the front door is a huge security weakness. More on this later in this post.

HifiCentret adds a cowling surrounding the reset button [see video location 3:17]. This only matters if the rear is accessible and since I intended to mount the safe flush to a wall, secured into the wall and sturdy shelving below, so I am not implementing the cowling.

HifiCentret cut a groove around the solenoid’s shaft to catch the bolt assembly during a “bounce open” attempt [4:15]. I have not yet done this, but I may because it is a feasible, reasonable solution.

HifiCentret reduced the gap between the solenoid and the bolt assembly. I have done this and, in my subsequent tests, I feel that it greatly hampers a “bounce open” attempt.[4:50]

HifiCentret strengthened the solenoid spring by stretching it. I have done this and feel that it is effective[5:30]

HifiCentret installed a physical barrier to prevent someone from puncturing the leftmost LED hole and inserting a wire for snaking over to the solenoid to push it down.[5:50] I did not install HifiCentret’s barrier because (1) I am only trying to protect against basically honest people that visit my home who would not deliberately deface the safe, or anything else in my home; (2) I discovered a far more egregious defect that can be exploited by a person that doesn’t mind deliberately defacing the safe, which I’ll discuss next.

The opening lever actuator (T-Bar) of my safe is totally made of plastic, including the shaft that extends into the safe’s cavity. See Fig 5, below. It is secured by a cotter pin. See Fig 6, below. Plastic may have been sufficient if the shaft that penetrated into the safe’s interior was within a steel tube but in my case the plastic shaft passes through a “pinky finger” size hole in the front plate with no protection inside. “Ben J’s” safe appears to have [1:48] a desirable steel opening lever actuator (T-Bar) with a short shaft. All of the current products that I see advertised today look identical to mine so, possibly, “Ben J’s” safe is of a different vintage or costlier design. Anyway, the flimsy plastic opening lever (T-Bar) on my safe would be easily snapped off with a stout screwdriver. Then, using the same screwdriver, the remaining plastic shaft could be pushed in, leaving a “pinky finger” size hole that would permit a “pinky finger” or tool (how about the same screwdriver) to press down the solenoid. See Figs. 6, 7 and 8, below. The absence of the steel tube surrounding the T-Bar’s shaft and the parts being made of plastic, makes this safe easy to be defeated by anyone willing to deliberately deface and damage the safe. I consider this safe to be only slightly better than a locked wooden desk drawer – or possibly of a comparable level of security.

Fig 5. – Actuator Handle (T-Bar)

Fig. 6 Actuator Shaft Inside View

Fig. 7 – Actuator shaft Inside View

Fig. 8 – Finger through Large actuator Shaft Hole

There is more! The metal thicknesses are disappointingly thin. Actual measurements are shown in the clickable (to enlarge) images below.

pinky

The steel bolts, which are robust looking, are flimsily attached by peening to the bolt slide, which itself is only 1.13mm thich. See Fig. 9, below.

Fig. 9 – Peened Bolt Attachment

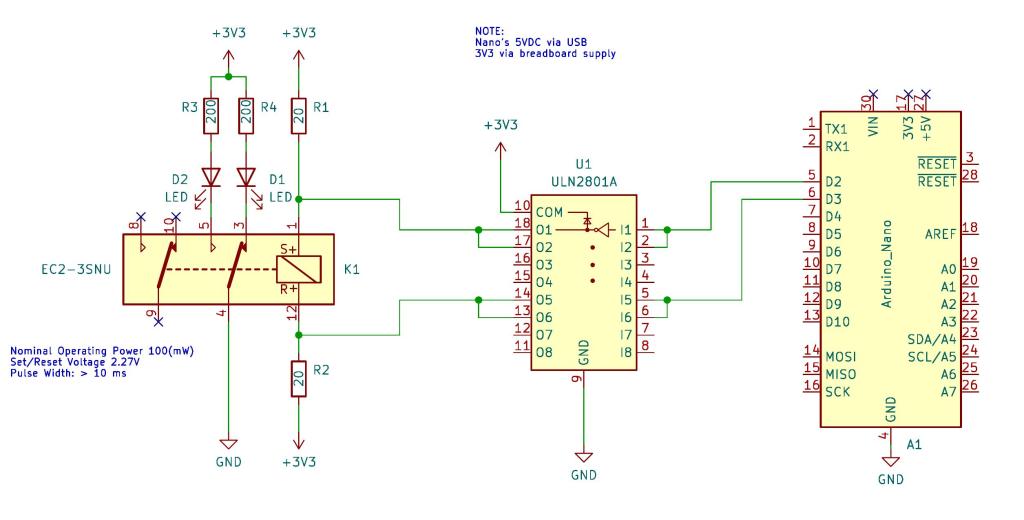

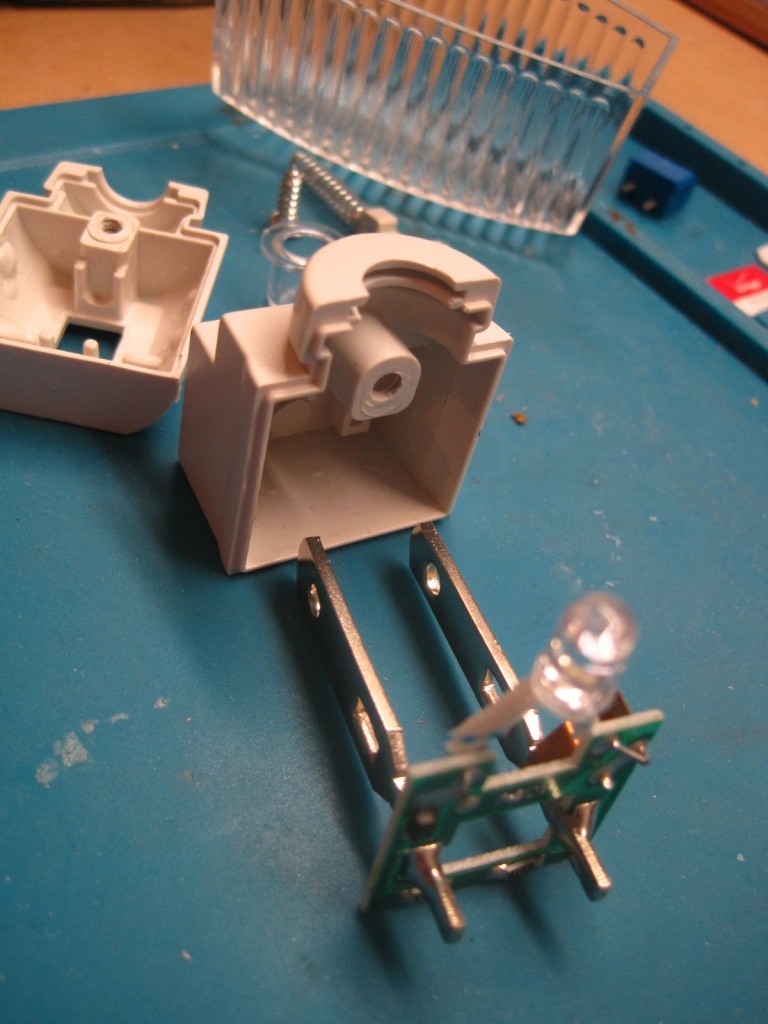

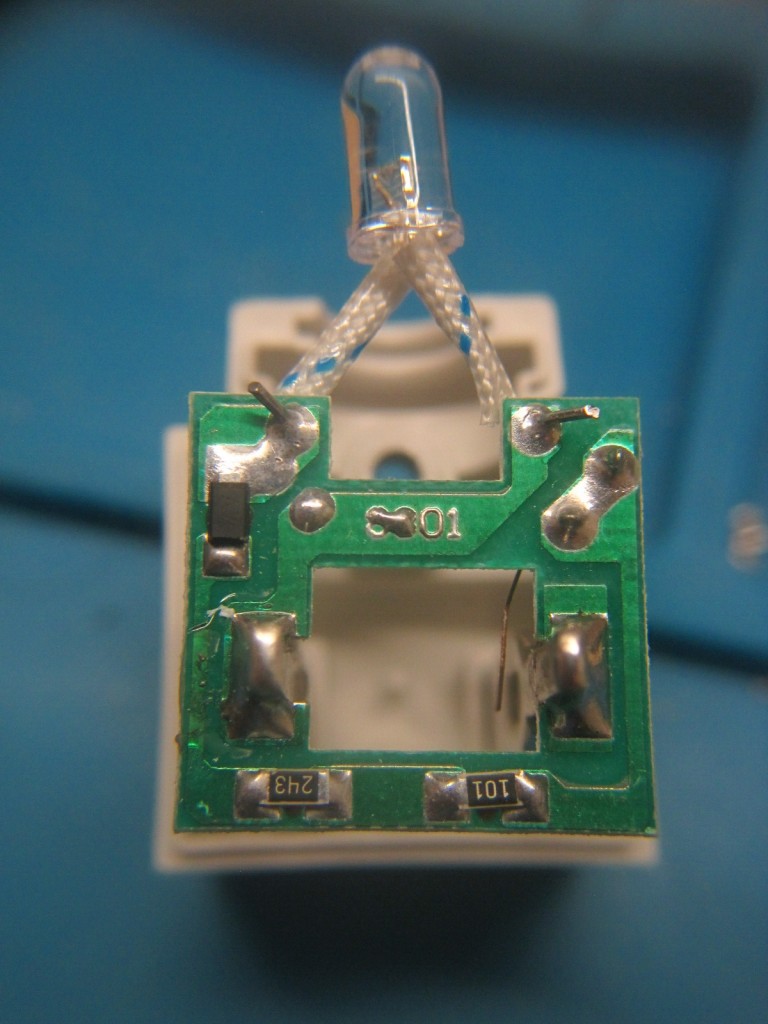

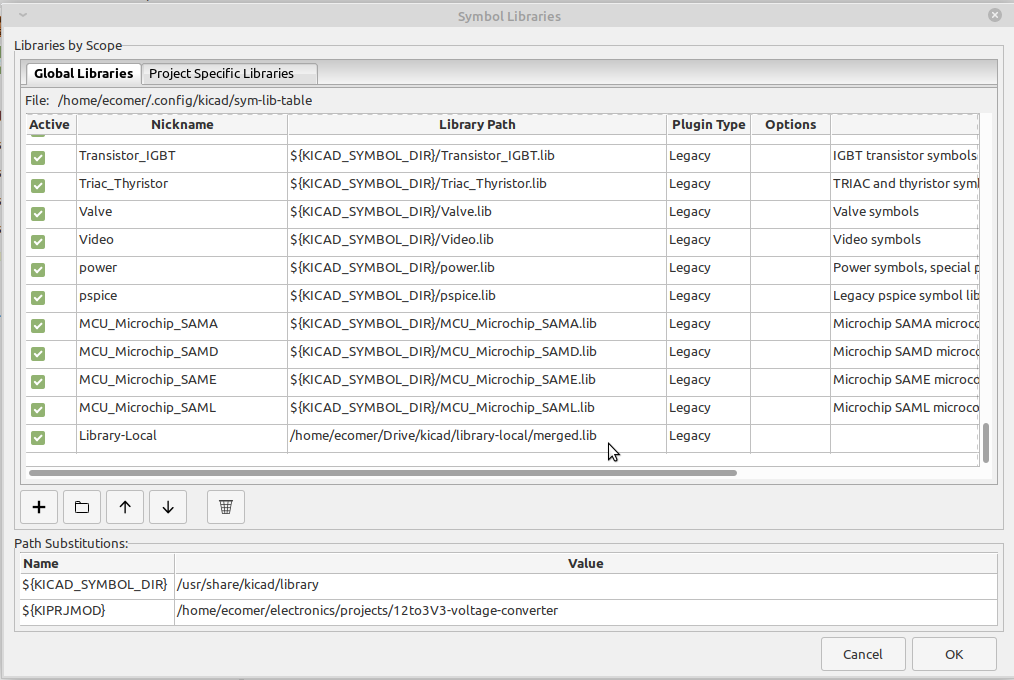

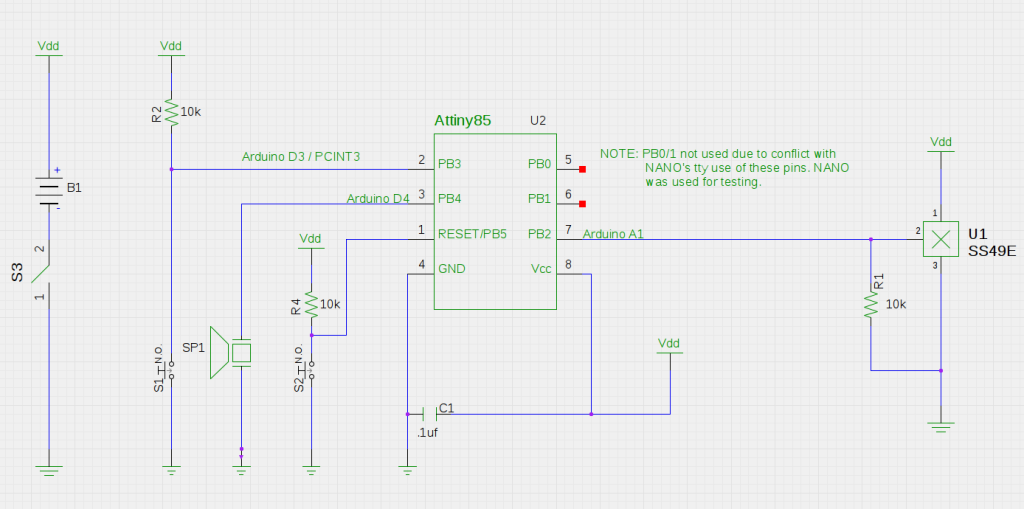

My last figures aren’t a criticism – I’m showing the electronics board for completeness in Figs 10 & 11, below. The PCB is a single-sided Printed Circuit Board that utilizes an ELAN Microelectronics (Taiwan company) EM78P153S One-time programmable 8-bit microprocessor. Fig. 11 is a reverse-engineered schematic of the board. Note – there could be a slight error somewhere in it as it was done rather hastily.

Fig. 10 – Printed Circuit Board (PCB) Front View

Fig. 11 – PCB Schematic

Bottom Line: This safe is useless against a true thief but may be of some limited value to keep certain items from the eyes and fingers of basically honest people that visit, such as visiting tradesmen, cleaners or house guests.

-

Credit: Solenoid mechanism diagram is a link to Jaime Capra’s website that reviews “Best Small Gun Safes”.